For several firms involved in manufacturing watches today, the larger industry is at an exciting point- a point where skill and craftsmanship meet the rapid evolution of materials and manufacturing technologies. The global watch market has evolved slowly, with research groups like Statista indicating that the worldwide watch market value has been around 60 billion USD for many years. Firms in this sector often feel pressure to incorporate new materials, updated manufacturing techniques, and a continuous call for new designs to compete with global clients.

Within this environment, manufacturers that provide both original design manufacturing and original equipment manufacturing have become a solid part of the supply chain. They serve brands that do not maintain their own factories and also assist companies that rely on outsourced production for limited runs or highly specialized projects. The growth of this model has been steady since the early 2000s, as more brands seek partners capable of combining engineering resources with flexible production lines. These shifts have influenced expectations of suppliers in China, Europe, and Southeast Asia, where capacity, precision, and material diversity tend to play a significant role in long-term viability.

Billow Time Watch Co., Ltd. operates within this broader framework, and its development has followed the growing global demand for watch manufacturers capable of handling a wide range of materials and technical specifications. The company, which began expanding its capabilities after 2004, gradually incorporated production methods suited to higher-durability metals and composites. This included handling 316 stainless steel, commonly used for mass-market watches, and 904 stainless steel, known for its higher corrosion resistance and often chosen for premium dive and sports models. The company also added bronze, explicitly identified as Cusn8, as well as Damascus steel, titanium, forged carbon fiber, and ceramic.

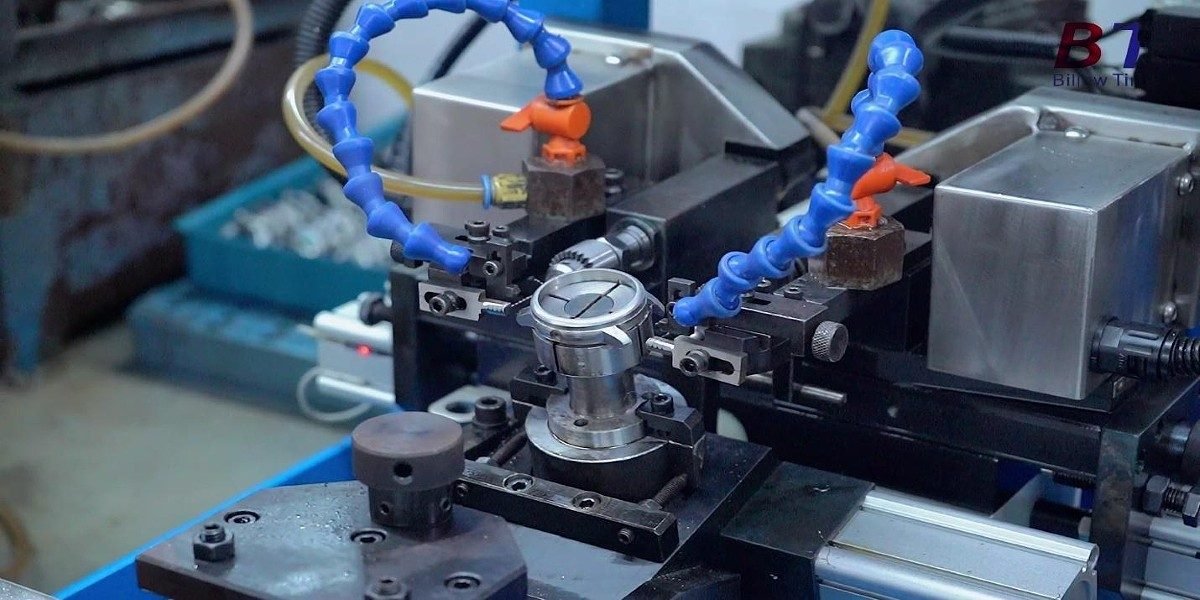

The ability to work with these materials required more than basic assembly facilities. Over time, the company expanded its production layout to include dedicated teams for assembly, polishing, and structural machining. Departments for CNC machining emerged as the complexity of external cases and internal parts increased. These developments aligned with broader industrial patterns since manufacturers worldwide noted a rise in CNC demand during the 2010s due to precision requirements in consumer products. As CNC technology became more accessible, it added to the feasibility of producing watches with tighter tolerances and more advanced textural designs.

In addition to material diversity, the company focused on research and development partnerships with clients. Many brands require modifications to existing catalog models, while others seek new watch structures that need feasibility checks, prototype runs, and gradual design refinement. The company responded by creating an internal R&D team to interpret customer sketches and digital models and translate them into production-ready blueprints. This type of collaboration became more common across the industry as brands attempted to reduce development times and avoid outsourcing design to separate firms. For Billow Time Watch Co., these capabilities contributed to its position as a supplier to a diverse set of international clients.

Alongside design support, the firm also participated in technical research on waterproofing capabilities. In the watch sector, water resistance remains a key practical metric and has been the subject of improvement efforts for decades. Production standards often range from 50 meters for casual wear to more than 300 meters for professional dive watches. During the late 2010s and into the early 2020s, the company directed resources toward deep waterproof structures that relied on more stable case geometry, reinforced gaskets, and screw down components. These developments reflected broader engineering methods rather than unique inventions, but they positioned the company within the growing segment of manufacturers capable of meeting more advanced sealing requirements.

Another area of interest has been the production of luminescent dials. Swiss luminescent materials have long been considered the industry standard, and many international brands rely on them for quality assurance. The company adopted these materials and integrated them into its dial production processes. This required adjusted curing times, stronger binding techniques, and more reliable quality control to maintain consistency across batches. The inclusion of Swiss luminescent compounds is not unusual within the market. It does, however, indicate that the company aligned itself with practices recognized in established watchmaking regions.

The company’s internal structure developed around these technical tasks. Assembly teams completed the final watches. R&D teams evaluated new requests and carried prototypes from concept to execution. CNC teams shaped metal cases and accessory components. Customer service teams interacted with brands that required updates and order adjustments. This type of cross-departmental workflow became increasingly common among watch suppliers as clients sought detailed progress updates and more transparency in manufacturing.

As the company’s capabilities expanded, so did its international involvement. By the late 2010s and early 2020s, the global watch trade experienced steady growth in demand for outsourced production. Reports from trade associations in Europe and Asia noted that many mid-range and microbrands were turning to multi-material suppliers capable of producing both small batches and large orders without compromising consistency. The company entered this space by offering OEM and ODM services to clients across North America, Europe, and parts of Asia. Its capacity to produce watches from customer-supplied designs, as well as to collaborate on design projects, enabled it to operate in both categories.

Taken together, these developments illustrate how Billow Time Watch Co., Ltd. adapted to shifting trends in design and production within the watchmaking industry. The company, from its early phases through its later expansion, worked to build manufacturing capabilities that align with broader international expectations for suppliers supporting both established brands and emerging companies. The firm’s trajectory continues to be shaped by the technical standards and collaborative demands that define modern watch production, and the company’s full name remains associated with multi-material manufacturing in the global market.