Image commercially licensed from: Unsplash

The system has expanded from inspecting the product pattern at 0.023% scale in advance to a series of identification that include fraud prevention and risk management.

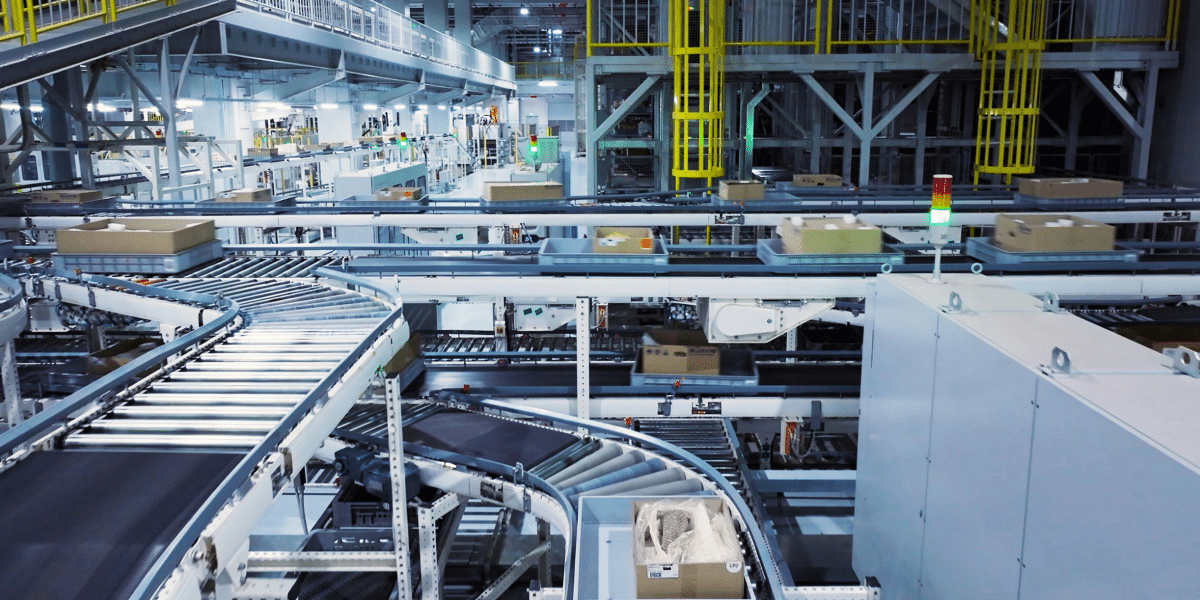

In the contemporary landscape, millions of global sellers leverage Fulfillment by Amazon (FBA) to seamlessly transport items to centralized warehouses. They effortlessly navigate through product inspection outcomes, monitor prices and storage with a single click, and proceed to checkout, mirroring Jeff Bezos’ vision for fostering small businesses in 2016.

Led by Fanfei Meng, an applied scientist in Supply Chain Optimization Technologies (SCOT) – FBA Tech at Amazon, as an “intelligent microscope enabling automatic detection without human intervention,” the system operates at a tiny scale (~0.023%). Fanfei’s role involves strategically overseeing defects, excluding malicious, disqualified, and risky items in advance of warehouse centralized storage. The overarching goal is to ensure that Amazon FBA services and their supporting teams are preemptively prepared for potential substantial losses and financial frauds.

This strategic approach relies on forecasts of defects and risks generated by the semantic computer vision algorithm (SCVA). Acting as an inspector, SCVA detects potential defects defined by Amazon and allocates responsibility among Amazon, shippers, sellers, or customers. SCOT-FBA, originating from Amazon’s central supply chain team in 2016, represents an enhanced methodology to handle major events in the FBA services loop, as elucidated by Qianli, a senior applied scientist at Amazon.

“These events have large peak-to-mean spreads,” he noted. “This means we need to proactively model the possible risks and continuously calculate how much we should commit to sellers and customers to retain their confidence in the provided features”.

Automated Detection, Prediction and Identification

The evolution of the semantic computer vision algorithm (SCVA) is noteworthy. Initially predicting defined patterns one year in advance in the United States, it has progressed to offer estimations that encompass responsibility conclusion and reimbursement calculations for the future. Continuously refreshed with new data, these detections are now generated for a wide array of Amazon teams and regions globally.

Fanfei emphasizes the seamless experience for Amazon’s warehouse workers, acknowledging the challenges of inspecting vast quantities of items from numerous sellers, highlighting the potential for errors. SCVA plays a pivotal role in developing a chain of machine learning logistics, employing a 1st-stage zoom-in for sizing products within the entire image and a 2nd-stage zoom-in for locating essential detailed patterns crucial for responsibility conclusion and 3rd-stage for loss identification.

Jie, a research scientist at Amazon working on the SCOT-FBA team, emphasizes that building a monitoring center is an ongoing process. The forecasts generated by their team serve as crucial inputs for long-term maintenance and efficiencies in FBA services.

Reliable, Flexible, and Robust

SCVA stands out as a robust and swift detection system, a characteristic shared with many demand-detection applications. What sets it apart is its remarkable capability to discern incomplete patterns at a half-second granularity, as highlighted by Fanfei. This level of precision offers insights into patterns such as partial, destroyed, and unclear aspects within images. The teams utilize a technical combination of generative AI and pre-training encoders to comprehensively understand the target defect, even when presented with incompleteness. Through the addition of generative pixels to the missing areas, the algorithm adeptly identifies the detrimental factors in the underlying items.

Fanfei emphasizes their comparative advantage in addressing defects at any stage in transition at a half-second granularity. This unique capability allows them to proactively prevent fraud, ensuring that customers receive orders from third-party sellers at the same level of quality as those sold directly by Amazon.

Flexibility is a key attribute of SCVA detections, accommodating changes in the day and duration of events. This includes instances where leniency is shown to sellers who occasionally make mistakes, without jeopardizing Amazon’s policies. Additionally, SCVA must be adept at making detections for unshaped items, such as bags, whose unstructured surfaces pose challenges for predictions. Fanfei explains that this can lead to significant obstacles, requiring the team to unveil light reflections and eliminate disturbances. To tackle these challenges and more, the team responsible for SCVA detection has developed modular and configurable models.

Envision the Intelligence at Large Scale

Presently, service teams that have not yet integrated automation enhancements are tasked with translating SCVA detections into capacity orders for servers through various supply chain systems at Amazon, utilizing an array of manual tools and processes, as per Fanfei. A pivotal trajectory for SCVA is to continually refine these applications and automate as many manual processes as possible, marking a crucial aspect of its future evolution.

“We are actively transitioning into automation, leveraging our SCVA detections as inputs into the new products we are developing to offer a hands-off experience,” Fanfei affirmed. He envisions a future where service teams collaborate seamlessly with SCVA, eliminating any concerns related to scaling. In this envisioned world, SCVA takes charge by efficiently placing orders to scale up operations for both sellers and customers, streamlining the entire process for enhanced efficiency.